The Airtac Solenoid Valve 4v210-08a Datasheet is an indispensable resource for anyone working with pneumatic control systems. This document provides critical information about a widely used and highly reliable solenoid valve, essential for automating various industrial processes. Understanding the details within the Airtac Solenoid Valve 4v210-08a Datasheet ensures correct selection, installation, and operation, leading to efficient and safe machinery performance.

Understanding the Airtac Solenoid Valve 4v210-08a Datasheet and Its Applications

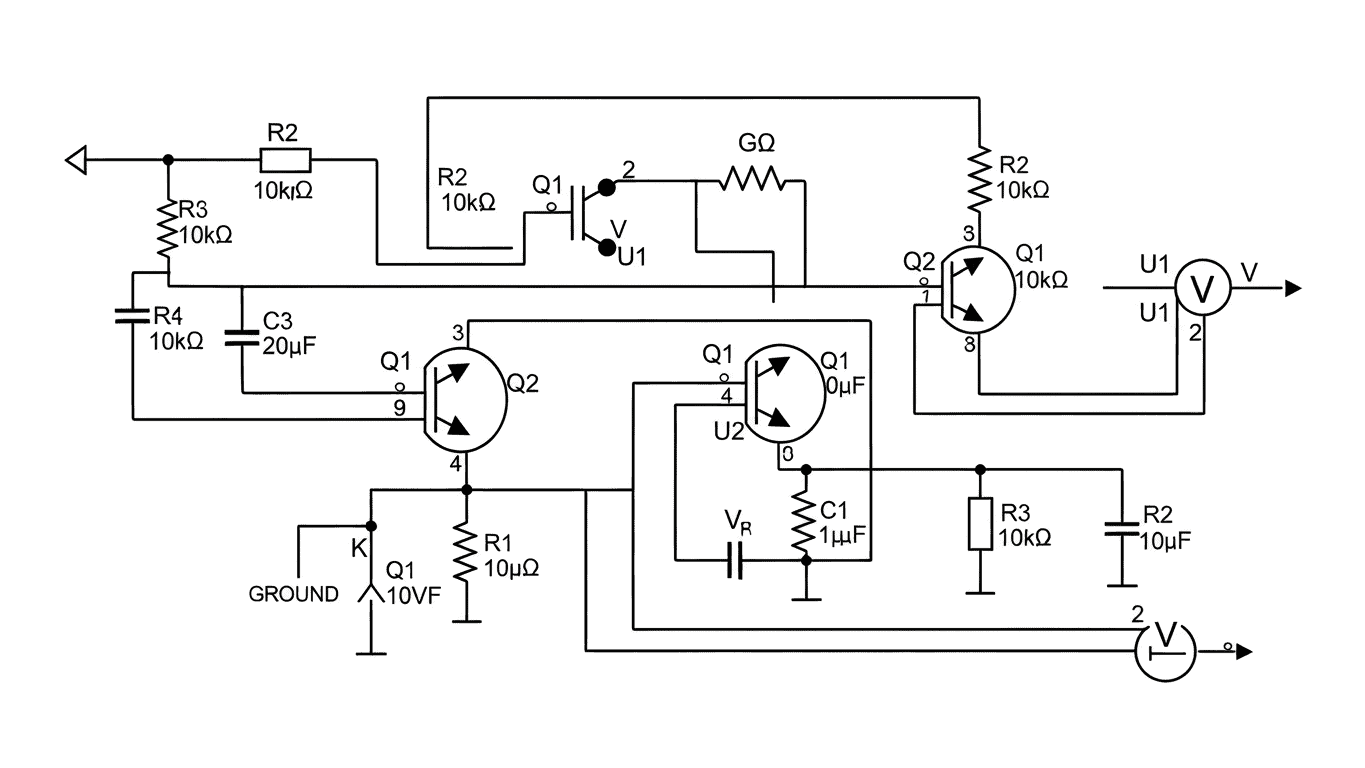

The Airtac Solenoid Valve 4v210-08a Datasheet is essentially a technical blueprint for a specific type of pneumatic valve. Solenoid valves are electromechanical devices that use an electric current to generate a magnetic field, which in turn operates a plunger. This plunger acts as a switch, controlling the flow of compressed air. The 4v210-08a model is a 5-port, 2-position (5/2 way) solenoid valve, meaning it has five connection ports and can switch between two distinct operational states. This versatility makes it suitable for a broad range of applications. The importance of this datasheet lies in its ability to provide precise specifications, allowing engineers and technicians to select the correct valve for their specific needs and ensure compatibility with existing systems.

The information contained within the Airtac Solenoid Valve 4v210-08a Datasheet typically includes:

- Electrical specifications (voltage, current consumption, duty cycle)

- Pneumatic specifications (port size, operating pressure range, flow rate)

- Dimensions and mounting details

- Operating temperature range

- Materials of construction

- Service life and maintenance guidelines

These valves are extensively used in:

- Automated Assembly Lines: Controlling the movement of robotic arms, grippers, and actuators.

- Packaging Machinery: For precise control of pneumatic cylinders that open, close, and move components.

- Textile Machinery: Managing the intricate movements of various parts in looms and other fabric production equipment.

- Industrial Automation: As a fundamental component in building complex control circuits for diverse manufacturing processes.

A typical application scenario might involve using the 4v210-08a to control a double-acting pneumatic cylinder. When the solenoid coil is energized, it shifts the valve, allowing compressed air to enter one port of the cylinder and exhaust air from the other, causing the cylinder to extend. De-energizing the coil reverses the air flow, retracting the cylinder. The datasheet will clearly outline how to connect the air supply, the cylinder ports, and the exhaust ports for optimal performance. For instance, the following table might be found, detailing port functions:

| Port Number | Function |

|---|---|

| 1 | Air Inlet |

| 2 | Cylinder Port A (e.g., for extension) |

| 3 | Exhaust (from Port B) |

| 4 | Cylinder Port B (e.g., for retraction) |

| 5 | Exhaust (from Port A) |

For detailed technical drawings, electrical connection diagrams, and performance curves specific to the Airtac Solenoid Valve 4v210-08a, please refer to the comprehensive datasheet provided by the manufacturer.

To ensure your pneumatic systems operate at their peak efficiency and reliability, consulting the dedicated Airtac Solenoid Valve 4v210-08a Datasheet is your next essential step. This document is your authoritative guide to understanding and implementing this critical component.